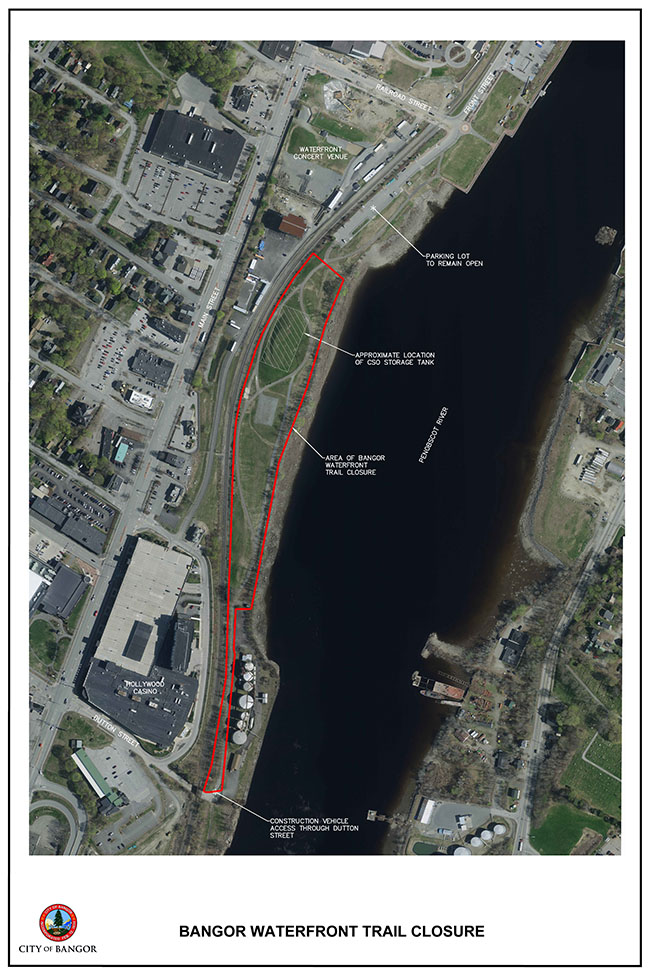

Davis Brook CSO Storage Tank

Work completed 5-2-22 to 5-20-22

S.E. MacMillan began loaming, seeding and mulching the area of the Tank site over the Tank top and between the walkways on Monday, May 2nd.

On Tuesday, May 3rd, MacMillan placed concrete for every fourth fence post hole along the railroad right-of-way fencing.

Lyford Hydroseeding was on site on the 4th of May and hydroseeded over Macmillan’s seed and mulch.

By Friday the 6th , SEM had finished loaming, seeding and mulching from the north end of the site to the electrical building and sediment pond.

SEM began fine grading the walkways on Friday May 6th.

SEM fine graded the walkway and driveway around the hatches for dewatering chamber #2.

Roundy Paving used 250 tons of mix to pave the walkways on May 11th.

SEM painted the 48” diameter ductile iron vent stack Navy blue.

Express Electric installed the new control cabinet and wired the Rotork actuators for the 42 and 48-inch slide gates.

MacMillan touched up the loam and seed around the entire walkway and Lyford hydroseeded on Friday, May 20th.

Work Completed 4-18-22 to 4-29-22

On Monday, April 18th Express Electric worked on wiring inside the CSO electrical building. S.E. MacMillan graded the walkway in front of the electrical building and began loaming, seeding and mulching on the north end of the site.

SEM started grading the Roundhouse fill site behind Geaghan’s brewery expansion. Some areas of the stockpile are too wet to grade and SEM has been trying to reach and smooth those areas with an excavator so water will shed rather than collect and further saturate the fill.

SEM loamed, seeded and mulched an area north of the Tank and along the east side. Lyford Hydroseeding hydroseeded over SEM’s mulch.

Representatives from Vaugh Pumps, Rotork Actuators and Grande Tipping Buckets were on site Tuesday the 26th. They performed some inspections and preliminary testing. All three chopper pumps were pulled, oiled, had impeller rotation checked and the pumps were reset into place. The pumps were run for a short while to verify that dewatering valves, flow meters and pressure sensors were all functioning. The tipping buckets were inspected on the inside of the three Tank cells and all nine tipping buckets were filled and dumped.

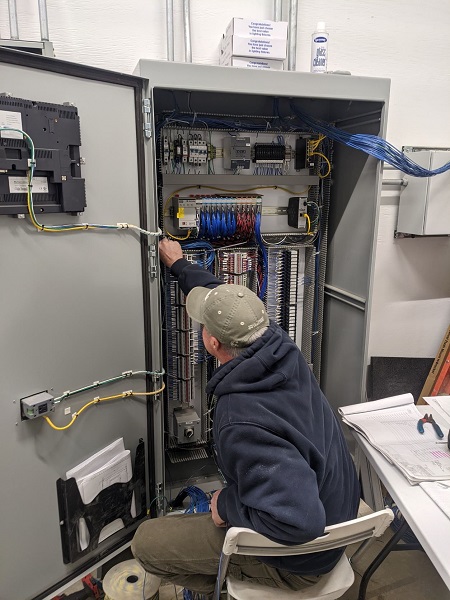

Wright and Pierce Engineering had a representative on site April 28th and 29th, working inside the PLC cabinet and checking on programing for SCADA communication between dewatering and water supply.

SEM successfully pressure tested the three-inch water supply line for the tipping buckets on August 28th.

Express Electric has completed all the process wiring and is nearly finished work on the CSO electrical building. They installed exterior and interior lights and emergency lights during the last week of April.

SEM began work on the sedimentation pond. Concrete Coring of Maine was on site to core a sixteen-inch hole for the pond drain structure.

SEM excavated, put down filter fabric, underdrain piping and the soil media for the pond which will catch rainwater flow off the Tank’s grassed surface.

SEM began reinstalling the railroad right-of-way fencing on Friday, April 29th.

Work completed 4-11-22 to 4-15-22

On Monday S.E. MacMillan placed the chimney walls for the north access hatch to the Davis Brook conduit. They stripped the forms on Tuesday and applied damp-proofing to the exterior face. SEM began final grading for the Roundhouse fill site this week.

Express Electric pulled the two-foot by four-foot slab meant for the LP-3 cabinet and re-set a second one pre-cast by SEM measuring four-foot by five-foot. The LP-3 cabinet to be used by Parks and Rec is about seven feet tall and needed a larger base.

SEM placed forms to place concrete around the stainless-steel hatches in the north and south hatch access locations. The hatches are on order. They loamed, seeded and mulched up to the formwork.

Express Electric installed the meter socket and disconnect for the LP-3 cabinet. They spent most of the week wiring process equipment inside the electrical building.

Work completed 4-4-22 to 4-8-22

S.E. MacMillan placed eight cubic yards of Hughes Brothers concrete for the south hatch slab on Monday, April 4th. Alex Willard from S.W. Cole tested the concrete and took a set of cylinders.

Express Electric continued wiring. They pulled wire for water supply valve actuators on Monday and Tuesday this week.

Versant Power was onsite Wednesday and Thursday. They pulled the primary cables, set the transformer and energized the service for the Davis Brook CSO Tank and electrical building.

SEM placed Hughes Brothers concrete for the south hatch chimney walls which will support the stainless-steel access hatch.

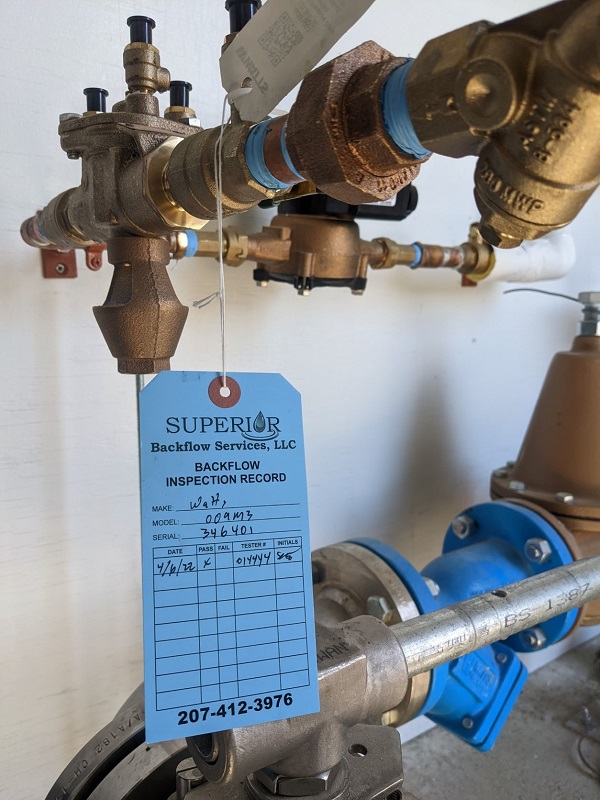

Superior Backflow Services visited the site Wednesday and tested the three-inch and ¾ inch backflow preventers in the water supply meter room of the electrical building.

SEM stripped the formwork and damp-proofed the south hatch chimney walls.

SEM set frames for the electrical handholes.

On Friday, ahead of the heavy rain later that day, SEM placed Hughes Brothers concrete for the north hatch slab. Logan Henderson, an S.W. Cole technician tested the concrete and made a set of cylinders.

Work completed 3-28-22 to 4-1-22

Express Electric worked during the early part of the week wiring for tipping bucket actuators inside the PLC control panel.

S.E. MacMillan uncovered the precast concrete planks covering the tipping bucket bays in order to re-seal their Tank contact points. These seams were dripping water inside the Tank this winter.

SEM set the last light pole base on the south end of the site. All the light poles are in place, wired and operational, although they will remain turned off until all the site surface restoration is complete.

SEM began work on the two new hatch entrances on the 8’x9’ Davis Brook conduit.

They cut a three-foot by four-foot opening in the precast box culvert. This conduit was built in 1999 using rectangular precast pieces eight feet wide, nine feet tall and eight inches thick. The seams were sealed with an asphalt-based gasket.

SEM began final grading of the site base prior to putting down loam. Loam and seed will start in mid-April.

The south hatch entrance was formed and reinforcement steel was tied.

The slab being placed over the Davis Brook conduit will span the conduit. Large concrete blocks were placed against the conduit and reinforcement steel was doweled into the blocks so that the reinforcement mats span over the top of the precast conduit. Insulation was placed between the top of the conduit and the bottom of the slab for structural separation. This new slab will act as an arch and support the chimney which the new aluminum hatch entry will rest on. SEM will place the south hatch slab on Monday.

Davis Brook CSO Storage Tank

Work completed 3-21-22 to 3-25-22

S.E. MacMillan started setting light poles on Monday the 21st. A separate crew continued setting new concrete light pole bases and a third crew began pulling wire under the supervision of electrician Scott Kenny.

There were twenty-four bases and poles inside the Tank site, sixteen of them were planned to be relocated because of the new Tank excavation and another eight were moved because of their proximity to the work and the potential damage due to construction traffic.

The Tank site is drying as the frost is coming out of the ground. SEM has encountered less frozen ground this week while excavating for light pole bases.

Work will begin next week on the north end of the site to build the new paved walkway which will pass along the edges of the bases.

Express Electric worked with SEM to set the pre-cast pad for the new electrical cabinet near the northeast Tank corner.

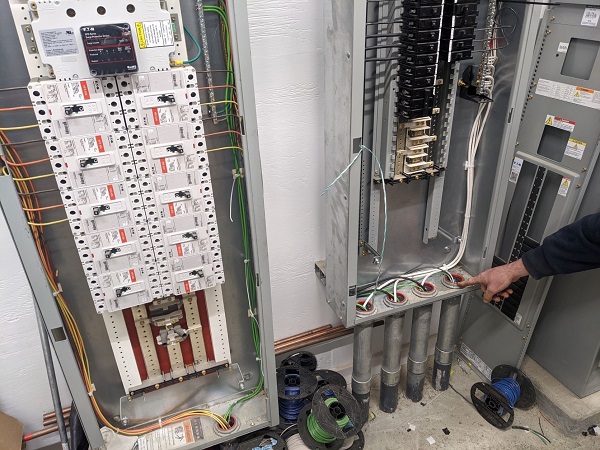

Express Electric worked inside these 480V (left) and 120V(right) cabinets this week wiring valve actuators, heating units, lights and receptacles.

Davis Brook CSO Storage Tank

Work completed 3-14-22 to 3-18-22

Express Electric worked this week on wiring in Dewatering Chamber #2. They pulled wire to power gate valve flow control actuators, pressure gauges and the flow meter. In order for the pumps to operate as designed the flow and pressure of the discharge has to be measured constantly and the flow control gate valve adjusted accordingly to allow the pumps to run in a smooth rpm with minimal surge.

Express Electric will have Dewatering Chamber #2 ready for power by the end of next week. Versant Power is expected to be onsite before the end of March to pull the primary cable, set the new transformer and energize the service.

Dylan Fortin connected the Main Breaker section of the Motor Control Center which arrived this week. The delivery was a couple weeks early. Express Electric dismantled the temporary disconnect they had assembled and began wiring in the Main Breaker and connecting it to the rest of the MCC.

S.E. MacMillan began work on light poles. They precast fifteen light pole bases on site this week.

SEM also began setting bases and laying conduit, ground rods and ground wire. Scott Kenny supervised the installation while rewiring light pole lamps on site.

On Friday Scott Kenny and SEM pulled wire for ten light pole bases.

Davis Brook CSO Storage Tank

Work completed 3-7-22 to 3-11-22

Sean MacMillan and Rick Merrithew added a barrel section and new flat top to an existing drainage structure at the base of the retaining wall and abutment for the I-395 Penobscot River Bridge. S.E. MacMillan has begun final prep work for final filling and grading of the Roundhouse fill site. The Roundhouse site is the former location of the locomotive engine garage, or “roundhouse” for the Maine Central Railroad. The City of Bangor took ownership of the Roundhouse site and most of the Maine Central waterfront property in the early 1990’s.

Thornton Construction, as part of their work on the Maine Savings Amphitheater concert venue, has started hauling excess material to the Roundhouse site.

MacMillan built forms to pre-cast five concrete pads, four of which will serve as entrance pads for the electrical building, the fifth will be support the building’s air conditioning unit. With completion of most of the work inside the Tank, MacMillan is focusing on outside work which can be accomplished prior to frost coming out of the ground. They concentrated this week on site clean-up and moving material and equipment off-site.

Express Electric installed pull strings and pulled wire from the Motor Control Center to dewatering chamber #2 hand holes and then into the dewatering chamber itself.

MacMillan placed concrete for the five concrete pads, finished, insulated and covered them.

Davis Brook CSO Storage Tank

Work completed 2-28-22 to 3-3-22

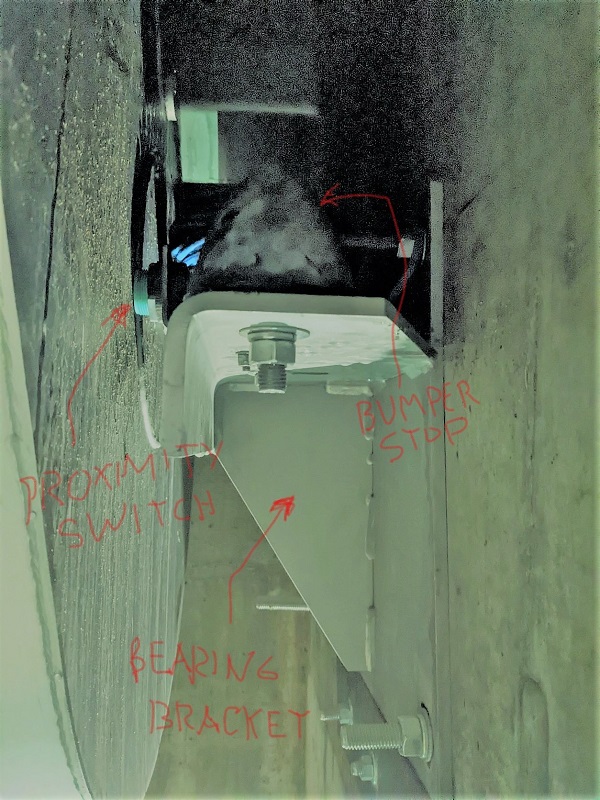

S.E. MacMillan worked inside the Tank this week on grinding down rough concrete edges and patching over areas where temporary formwork anchors have been removed. In the photo above Ian Hotham is footing the ladder for Rick Merrithew while Rick installs proximity switches on the tipping bucket bearing plates.

This photo shows a tipping bucket on the left and the green proximity switch which is threaded into an L-bracket mounted on the bearing plate of the bearing bracket. There are two bumper stops, one on each side of the bearing bracket, each is a dense rubber nodule which is a shock absorber-stop for when the tipping bucket is empty and at rest and when it has tipped and dumped. The face of the proximity switch needed to be exactly ½” from the side of the tipping bucket.

Rick Merrithew and Seath Fortin used a snake inserted into the conduit from the water supply chambers to pull the proximity switch wire from the Tank into the water supply chambers. Each tipping bucket has a proximity switch for monitoring flush activity. These switches are wired to the PLC or Programmable Logic Controller where Tank function information is gathered and sent to operating technicians at the Waste Water Treatment Plant.

The large cabinet on the right is the Programable Logic Controller.

Express Electric installed the electrical panel for the Parks and Rec side of the electrical service. Next to it mounted on the wall is the hot water heater for the bathrooms.

The Parks and Rec service is fed from the existing panel and cabinet installed in 2008 during the second phase of Waterfront Park development.

Express Electric installed a temporary disconnect in order to have a temporary fused entrance when the service is energized. The main breaker for the entrance is not scheduled for delivery until early April.

Wall mounted electric heaters were installed in both bathrooms this week. At the end of the week Seath and Dylan Fortin, from Express Electric, began pulling wire for lights, receptacles and heaters.

Davis Brook CSO Storage Tank

Work completed 2-21-22 to 2-25-22

S.E. MacMillan had a crew working inside the Tank all week; grinding rough concrete edges, removing epoxy injection fittings, filling injection fitting holes in the base slab with hydraulic cement and drilling more holes in the base slab of Tank Cell #3 for more epoxy injection.

Rick Merrithew applied coats of hydraulic cement onto both plugs of the 48” Tank inlet pipes. Both of these masonry plugs have been leaking during high-flow events in the Davis Brook box culvert due to recent rain and snow melt.

The above photo is Tank Cell #3, water on the floor is a combination of cleaning water, condensation dripping from the ceiling and some ground water bleeding up through the Tank base slab.

On Tuesday, Paul Buchanan of Buchanan Mechanical, installed a ¾” copper water line for an exterior hose bid outside of the water meter/storage room door.

Paul installed the lavatories and toilets in both bathrooms and Earl Grover mounted mirrors, grab bars, soap and paper dispensers.

Express Electric erected both transducer cabinets for dewatering chambers 1 and 2. Seath and Dylan Fortin pulled wires for both Cell #1 sump transducers from the transducer cabinet into dewatering chamber #1. They hung the transducers into the Cell #1 sump and pulled the wire from the Tank into dewatering chamber #1.

The transducer wires were mounted to the hatch skirt concrete above the Tank chimney riser wall with drop-in anchors and supported with steel drop mesh cable for stress relief. The transducers hang roughly 35 feet below the hatch skirt at elevation -12.17.

Express Electric installed a temporary power disconnect which will be necessary for a short while after energization by Versant which will allow for lighting and heating of the electrical storage building. Seath Fortin said once the main breaker arrives and is installed (back ordered and due about April 1st) the temporary disconnect will be removed. Conduit work connections for Motor Control, transformer, lighting, water supply actuators, fire alarm, programable logic and radio control inside the electrical room is near complete.

Wednesday, the 23rd had a record high sunny temperature in Bangor of 65 degrees. It was welcome but recognized as a tease as the high on Friday the 25th was 12 degrees and work was suspended at noon due to heavy blowing snow.

Davis Brook CSO Storage Tank

Work completed 2-14-22 to 2-18-22

This week Express Electric worked inside the electrical room, they set the Programable Logic Controller (PLC) in place along with the fire alarm panel and the radio control panel. The PLC is an industrial computer which will allow automated control over the Davis Brook CSO pumps, valves and tipping bucket flushing systems. Technicians at the Bangor Waste Water Treatment Plant can remotely communicate with and control the Tank’s functions through the PLC. In the photo above the PLC is the largest cabinet to the right-center, to the left center is the 120-volt lighting/receptacle panel and left of that is the 480-volt distribution panel powering the flow control valves in the tipping bucket water supply chambers. The small black panel on the far left is the fire alarm panel and to the far right is the radio control panel.

With bathroom plumbing rough-in complete, S.E. MacMillan worked on insulating and finishing the south bathroom chase walls. They had a crew inside the Tank grinding rough concrete edges and cleaning. They did not receive the SIKA Epoxy for crack plugging they needed until Friday afternoon, next week they expect to complete the epoxy injection in the base slab.

Dylan Fortin cut, bent and threaded steel conduit inside the electrical room for mounting to connect power panels and the PLC with actuators, valves and sensors.

The US Coast Guard was in the Penobscot River again this week.

By the end of the week, Express Electric had better than half of the conduit connections installed inside the electrical room for fire, power, PLC and radio wiring. They expect to have the electric service meter socket inspection from City Code Enforcement next week and they’ll schedule primary power cable to be pulled, the transformer set and the Tank service electrical service energized by Versant in early March.

Davis Brook CSO Storage Tank

Work completed 1-31-22 to 2-11-22

On Monday, January 31st S.E. MacMillan cleaned up the nineteen-inches of snow that fell on Saturday. Express Electric had two men bending and mounting conduit inside water supply chamber #3. SEM had a crew inside Tank Cell #1 prepping to inject epoxy into shrinkage cracks in the base slab. There is a small but regular amount of ground water weeping into the Tank through these cracks. MacMillan will use the same method and material to plug these leaks as they did with the Tank walls during pre-backfill leak testing.

SEM drilled holes approximately ten inches deep into the slab where injection fittings are inserted.

They drilled holes into the concrete at about 45-degree angles and alternated sides of the crack at about a foot on center. The injection fittings have a rubber gasket that expands when tightened into the ¼” holes. MacMillan is using Sikafix Epoxy, pump ing it through the injection fittings, into the crack until it surfaces. The epoxy travels in the crack, sets up and seals the leaks.

Above; SEM is cleaning Tank Cell #1 after completing epoxy injection.

SEM started the same epoxy injection process in Tank Cell #2. Some of the moisture on the Tank floor has come from surface melt water leaking through the tipping bucket bays. The pre-cast concrete plank covers will need to be better sealed and final grading in the spring will keep water from puddling over them.

Above is Tank Cell #2; SEM drilled holes, set injection fittings and pumped in Sikafix epoxy sealant.

Above; in Tank Cell #2, there are two rows of injection fittings in the base slab in an alternating pattern on either side of a shrinkage crack. Ian Hotham connected the pump line and pumped epoxy into each of the fittings. SEM will need to continue with epoxy injection next week when they can take delivery of more Sikafix.

Buchanan Mechanical completed the ¾” water supply and installed the Bangor Water District’s meter.

Seath and Dylan Fortin from Express Electric installed cabinets for lighting and distribution along with setting into place the Motor Control Cabinet and the Programable Logic Cabinet.

Davis Brook CSO Storage Tank

Work completed 1-24-22 to 1-28-22

On Monday, January 24th, S.E. MacMillan excavated for and set into place the pre-cast electrical transformer base. Primary power will be fed through this structure and into the transformer to power the new Davis Brook CSO Tank, the site electrical storage building and public restrooms. Don King, from Versant Power was on site Tuesday to look at the base orientation, base drainage, conduit penetrations and grounding. Don indicated to Stanley MacMillan that once SEM has made a formal request for connection, Versant will need a couple weeks to schedule the pulling of conductors and setting the transformer into place. SEM anticipates primary power will be in place by the end of February.

On the 26th SEM and Express Electric ran the conduit from the transformer pad to the meter socket.

The Coast Guard had three ice breakers on the river Thursday the 27th.

Express Electric has completed Unistrut, conduit and panel work inside both dewatering chambers.

In dewatering chamber #2, Unistrut support, conduit and control panels are in place to power the gate valve actuators on the Tank dewatering lines. In the background of the above photo is the eight-inch dewatering line for Tank Cell #2, in the foreground is the eight-inch dewatering line for Tank Cell #3.

This is the three-inch water supply for the tipping buckets. Jeff Glidden fabricated the stainless-steel pipe supports and installed them this week. The ¾” riser off the three-inch stainless in the foreground will eventually feed the ¾” water supply for the public restrooms.

Damon Insulation completed insulating the three-inch and two-inch stainless-steel tipping bucket supply lines. This photo shows water supply chamber #3 with insulated supply lines, control panel and conduit. The blue valve actuators will be powered through the control panel mounted on the far wall. From left to right they control flow to the Tank Cell #3 tipping buckets in bays 3, 2 and 1.

Davis Brook CSO Storage Tank

Work completed 1-10-22 to 1-14-22

S.E MacMillan completed exterior trim and siding this week on the north gable end of the electrical/storage building.

SEM cut and bent reinforcement steel for the Davit Arm manlift base sleeves.

They excavated, built cover and laid down glycol ground heat lines at the Davit base placement locations.

Concrete for three of the Davit base sleeves will be placed against the hatch chimney risers over the three main Tank Cells. The reinforcement steel was doweled six inches into the existing hatch chimneys and secured with an epoxy adhesive.

SEM used a glycol ground heater to heat the Davit base excavations and to heat the placed sleeve concrete during curing.

Jeff Glidden fit and tacked the stainless-steel pipe, fittings, screen and backflow preventer into place for the three-inch water supply entrance feeding the tipping bucket flushing system. SEM will have a certified welder from Sullivan and Merritt on site next week to make the finish welds.

The electrical/storage building’s exterior finish is complete.

Davis Brook CSO Storage Tank

Work completed 1-3-21 to 1-7-2

The last week of December S.E. MacMillan took delivery of four chopper pumps, one spare and one each designated for Tank Cells 1, 2 and 3. This week SEM installed the pumps.

SEM installed the last of the stainless-steel pipe support brackets which secure the eight-inch ductile iron discharge pipe and the two-inch stainless-steel pipe rail pump guides.

Tank Cell #2 as well as #1 and #3 has a sloped bottom with 1% pitch from below the tipping bucket flushing devices to the sump channel (seen above). The sump channel pitches about 2% from its’ high side to the chopper pump which is set into a sump that is about 4.5 feet deep.

SEM’s welder, Jeff Glidden, fabricated the stainless-steel support brackets on site using Type 316 stainless-steel stock.

Pipe supports bolted to the pipe were sleeved into a footed bracket anchored to the tank wall and welded into place.

Ahead of the pump installation MacMillan completed final pressure testing on the dewatering pipe from all three pump pedestals to gate valves inside the dewatering chambers. They used a flow-through test ball to apply test pressure and seal the pedestal end.

They used an excavator and a chain-fall rigged to the pump lifting bales to lower the pumps into place.

Each pump needed a small amount of pre-pumping to remove a few inches of water and expose the suction end of the pump pedestal.

The pumps came with guide rail adaptor brackets mounted to the horizontal discharge side of the pump.

This bracket slid easily into the guide rail system. Once the guide bracket and guide rail where connected the pump could be slowly lowered into the tank.

The guide rails are forty-feet long. They are bracket mounted to the Tank hatch ceiling, Tank wall and rest over nipples on the pump pedestal base.

The pumps friction mount on the pump pedestal with the guide bracket coupling to the pedestal with a simple crimp stop which enables a non-mechanical removal process should a pump need to be pulled for maintenance or replacement. The pumps weight holds it in-place, tightly sealed on the pedestal. A top-retrieval lift-rig mechanism will be installed so pump removal can be done from above the Tank. This guide system to be installed will enable a hoist mechanism to hook and lift the pump off the pedestal and up the guide rails.

These are Vaughn submersible chopper pumps with Baldor 30 horse power, 460V motors. Together the pumps and motors weight 1451 pounds. They have a six-inch intake with an 6x8 pedestal reducer. They are rated at 1700 gallons per minute at 30’ TDH. The spare chopper pump has been delivered to the Waste Water Treatment Plant.

Davis Brook CSO Storage Tank

Work completed 12-13-21 to 12-24-21

Together, during the second week of December, Enterprise Electric and S.E. MacMillan installed conduit and handholes for conduit from the electric building to both dewatering chambers

SEM cored openings for the twelve-inch dewatering pipe and the one-inch vent, connected both pipe into the Conduit with boots and placed concrete to support the 90-degree entrance into the Conduit. The six-inch electrical building 90-degree PVC sewer entrance into the conduit also received concrete for support with this placement.

On the 15th of December Enterprise Electric finished connecting conduit into dewatering chamber #2.

SEM set the pre-cast hatches on the water supply and Tank Cells. SEM is waiting on the delivery of the Davit base sleeves for the Davit Arm confined space manlift system.

Connection of conduit to dewatering chamber #2 was completed on December 16th.

SEM finished installing sheathing, trusses, bridging, ceiling fur, wall top plates, rafter vents, roof shingles, rake trim, soffit trim, soffit vent and ridge vent by December 17th.

SEM and Enterprise installed the conduit run for the water supply chambers December 17th and 18th.

SEM placed concrete around and over the water supply duct-bank where the paved walk passes over.

The last week of December, SEM insulated and put on the vapor barrier inside the electrical building,

and began installing siding and electrical fixture mounting panels.

Davis Brook CSO Storage Tank

Work completed 12-6-21 to 12-10-21

On Monday S.E. MacMillan set a manhole just outside the electrical building foundation. They laid six-inch schedule forty PVC pipe through the manhole, with a backflow preventer inside, all the way to the Davis Brook 8’x9’ box culvert sewer.

On Tuesday SEM successfully pressure tested all of the ten and twelve-inch dewatering pipe and connected the six-inch PVC electrical building sewer service into the 8’x9’ box culvert.

Enterprise Electric cored holes on Tuesday in the Tank for tipping bucket control monitors.

SEM, on Wednesday completed cleaning and paint touch-up for the dewatering pipe in both dewatering chambers.

SEM and Enterprise Electric laid four-inch PVC conduit for the primary electrical feed to the Tank and the electrical control building.

Earl Grover stood the premade wall panels on Monday and by Wednesday he and his crew were setting trusses for the electrical building.

On Thursday SEM laid six-inch ductile iron water main from the 8x6 hydrant tee and set the existing Waterfront Park hydrant in the new location next to the electrical control building.

Also on Thursday, Enterprise Electric and SEM laid conduit for the Parks and Rec side of the electrical service into the control building. One side of the building will house electrical and SCADA control systems for the Tank, the other side will have two unisex public bathrooms.

Friday, Earl and his carpenter crew began sheathing the control building roof.

Davis Brook CSO Storage Tank

Work completed

11-29-21 to 12-3-21

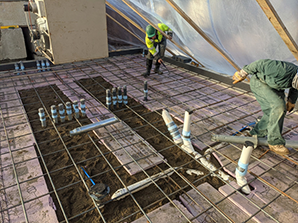

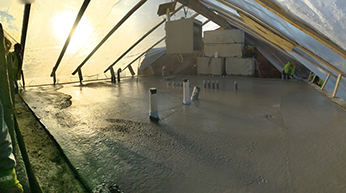

On Monday, Paul Buchanan, of Buchanan Mechanical, roughed in the plumbing for both bathrooms in the electrical building. On Tuesday S.E. MacMillan backfilled around the electrical and plumbing pipe and conduit, put down expansion joint and insulation. They tied a #5 bar reinforcement steel mat on one-foot centers.

This week Damon Insulation insulated the two-inch stainless-steel tipping bucket supply piping for all three tipping buckets and water supply chambers.

Enterprise Electric cored holes in the Tank and in water supply chambers for electrical and SCADA control conduit access.

On December 1st MacMillan placed the slab for the electrical building.

On Friday, Earl Grover, MacMillan’s carpentry sub started building walls to be set in place next week.

Davis Brook CSO Storage Tank

Work completed 11-15-21 to 11-24-21

S.E. MacMillan continued installing the dewatering piping in Cell #1 and dewatering chamber #1. They set the pedestal for the chopper pump in the sump for Cell #1. They are waiting for some pieces of ductile iron pipe to arrive which have been delayed. All of the in-ground dewatering piping – aside from connection to the Davis Brook conduit – is complete.

Inside the Cell #1 sump channel Nick Hotham used a small electric pump to dewater the chopper pump sump. SEM drilled and epoxied wedge anchors into place for mounting the chopper pump pedestal. Pumps and vertical pieces of eight-inch ductile iron dewatering piping are expected to arrive after Thanksgiving.

This is the sump for Cell #1, all three sump bottoms are the lowest points of the Tank, all three are at elevation -15.00, which is thirty-eight feet below finish grade.

Inside dewatering chamber #2, MacMillan connected pipe, valves, actuators and flow monitors. Dewatering chamber #2 houses the piping for dewatering suction lines for Cells #2 and #3.

Josh Burke bolted together the pieces of twelve-inch DI dewatering pipe exiting dewatering chamber #2.

Jeff Glidden fabricated the stainless-steel cap for the 48” Tank vent stack.

The cap was set in place before Thanksgiving. The vent’s finished look is to be determined and completed next year.

Davis Brook CSO Storage Tank

Work completed 11-08-21 to 11-12-21

This week Express Electric was onsite. Inside the foundation for the Electrical Building they roughed in the electrical and SCADA wiring conduit for power and data control of the Tank’s pumps and valve actuators. SCADA stands for “supervisory control and data acquisition”. The SACAD system installed in the Tank and its’ integration into the existing City of Bangor sewer SCADA system will enable remote control and monitoring of the Tank’s filling, flushing and dewatering. Specialized SCADA software enables Treatment Plant operators to computer monitor flow and capacity for the entire City sewer system.

S.E. MacMillan began installing dewatering pipe in dewatering chamber #1.

Inside dewatering chamber #1 Devon Haight and Ian Hotham bolted-up eight and ten-inch ductile iron pipes, valves and actuators. This chamber services the dewatering pump for Tank Cell #1.

Sullivan and Merritt completed welding and mounting two-inch stainless-steel supply piping for all three Tank cells. The photo above shows Rick Merrithew between water supply chamber #3 and the Tank installing Link-Seals in the Tank wall for the water supply penetrations.

Much of the north end of the site has been graded to within a foot of finish grade. Gravel subbase for paved walking paths and loam will still need to be put down.

Looking down the hatch chimney into the Tank, this photo shows SEM establishing a plumb line for installation of the pump pedestal and the eight-inch discharge pipe for Cell #1 into dewatering chamber #1.

Work completed 11-01-21 to 11-05-21

On Monday S.E. MacMillan finished laying eight-inch water main. They ran the new ductile iron pipe to the electrical building and off the eight-inch main stubbed the new four-inch service into the building and laid the six-inch lead for the new hydrant.

Also on Monday they set into place the 90 degree, four-foot diameter Tank Vent stack.

Beneath the vent elbow MacMillan excavated and put two feet of subbase stone, they laid a one-inch thick 8’x8’ piece of sheet steel and then placed eighteen-inches of concrete. On top of that they formed the base support for the Vent. The Vent will rise twenty-feet above finish grade and will vent the entire Tank.

On Wednesday MacMillan placed concrete for the Vent base support slab.

Also on Wednesday, Macmillan began connecting the water supply chambers with ductile iron supply piping. Due to availability issues, MacMillan substituted six-inch DI for four-inch DI and used mechanical reducers to connect to the three-inch stain-less steel supply vault piping.

MacMillan set a six-foot diameter pre-cast barrel section on the Vent support foundation around the short section of four-foot diameter Vent pipe. They placed concrete inside the barrel, covering the top of the elbow and the short riser mechanical connection.

Sullivan and Merritt came back on-site Thursday. They connected tipping bucket water supply 2” stain-less steel riser piping, shut-off valves and electric valve actuators for all three water supply chambers.

On Friday MacMillan belled a twenty-foot piece of four-foot diameter ductile iron pipe into place inside a second six-foot diameter precast barrel section and placed concrete inside the precast barrel. They also began fabricating a stain-less steel cap for the Vent stack.

Work completed 10-25-21 to 10-29-21

S.E. MacMillan tied reinforcement steel for the electrical building foundation and set the forms on Monday and Tuesday.

V.R. Concrete had two men on site Monday. They stripped the final form pieces from dewatering chamber #1, loaded all the remaining forms onto a trailer and moved off site. They will return once more to remove their crane.

SEM continues to fill and grade around the Tank. The photo above shows the northeast Tank corner.

The three water supply chambers are backfilled against their east sides. Sullivan and Merritt had three men on site later in the week installing the stain-less steel piping inside each chamber. The tipping buckets (above) on the left await the supply water piping which will come from the water supply chambers.

On Wednesday MacMillan placed 18 cubic yards of Hughes Brothers concrete for the electrical building foundation.

SEM began installing new eight-inch ductile iron water main on Thursday, connecting to the existing capped end on the north end of the site. The water main will run along the railroad right of way to the electrical building where it will be metered and split for separate services for public restrooms and Tank flushing.

Sullivan and Merritt installed the three-inch stain-less steel water supply piping inside the water supply chambers with 3x2 tee reducers. Each one of these two-inch risers will be run out of the supply chamber and through the three-foot thick Tank wall to a tipping bucket. Just above the flanges atop the two-inch risers, electric actuators and shut-off valves will be fitted to control the flow to the tipping buckets.

Work completed 10-18-21 to 10-22-21

VR Concrete placed 4 cubic yards Monday. The Hughes Brothers mixer arrived at 1:30 pm with concrete for the dewatering chamber #1 (DWC #1) sloped floor. They stripped the exterior wall forms of DWC #1 and prepped to form and tie reinforcement steel for the elevated slab.

S.E. MacMillan began setting tipping buckets (TB) into place on Monday. They set seven with two left to be set in Cell 2. They tested the first TB in Cell 1, filling it with water, it tipped and dumped the 1200 gallons perfectly against the backwall and spillway radius at the Tank bottom. The stainless-steel tipping buckets are fabricated to fill to a pre-determined level at which point the center of gravity shifts causing it to tip and dump the flushing water down and onto the Tank spillway. Once empty it returns automatically to its resting horizontal position.

Backfilling has progressed on the west side of the Tank. By Wednesday SEM had backfilled and compacted the Tank to about elevation 14.00 between DWC #2 and the vent stack penetration.

SEM cored holes in the water supply chambers on Wednesday. Each water supply chamber will house a supply manifold for three tipping buckets. SEM has hired Sullivan and Merritt to work off-site on welding the stainless-steel pipe and fittings for installation into the supply chambers. MacMillan will connect each of the three stainless-steel manifolds to the TB water supply main.

Anthony Havalotti put finish grade nails on the elevated slab form for DWC #1.

VR placed this elevated slab on Thursday using 10.5 cubic yards of Hughes Brothers concrete.

SEM backfilled against the north west end of the Tank on Friday, the entire west side is backfilled to elevation 15.00. They anticipate a pipe delivery next week bringing the 8” diameter ductile iron pipe they need for the new water main which runs at about elevation 11.00 between the tank and the railroad right of way.

Work completed 10-11-21 to 10-15-21

On Monday, VR Concrete placed 18 cubic yards of Hughes Brothers concrete, tested by Baxter Hughes of S.W. Cole, for the Dewatering Chamber #1(DWC #1) foundation slab. They also stripped forms from Dewatering Chamber #2 (DWC #2) walls, tied reinforcement steel and set wall forms for DWC #1. S.E MacMillan began drilling holes and epoxying stainless steel bolts for the tipping bucket bearing plates. They also continued backfilling with gravel on the top of the Tank, grading from the southern end toward the north.

VR placed 7 cubic yards of Hughes Brothers concrete on Tuesday for the sloped floor in DWC #2. They tied reinforcement steel and set forms for DWC #1 walls and stripped wall forms and began forming the deck for the elevated slab in DWC #2.

In the photo above; Dewatering Chamber #2 is in the foreground, DWC #1 is in the background. Along the west side MacMillan has backfilled to about elevation 9.00. Finish grade will be elevation 22.00.

Levis Boutin and Bob McKinnon formed the deck for the elevated slab over DWC #2.

VR tied reinforcement steel for both dewatering chambers on Wednesday. The bond-outs in the above photo are (on the right) for dewatering pipe gallery access and (on the left) for Cell #3 chopper pump installation, maintenance and removal.

Josh Burke and Ian Hotham set ledger plates in Cell #1, bay #1 for the tipping bucket brackets. Having these ledger plates in place allowed them to hold and steady the fifty-pound stainless steel bearing brackets while drilling holes in the Tank wall and epoxying mounting bolts.

VR placed 50 cubic yards delivered by Hughes Brothers on Thursday for the DWC #1 walls and DWC #2 elevated slab. They left the site for the week on Thursday afternoon.

Macmillan graded gravel on the top of the Tank Friday, put on damp proofing covered with filter fabric and continued installing tipping bucket bearing brackets. Next week they will install the tipping buckets.

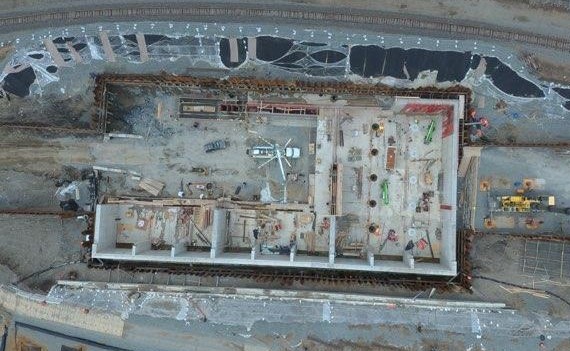

Work completed 10-04-21 to 10-08-21

On Monday, VR Concrete returned to the site, they tied reinforcement steel and formed the Dewatering Chamber #2 (DWC #2) slab. DWC #2 will house the dewatering piping connected to the Vaughn, 30 HP chopper pumps which will pump combined sewer overflow from the Tank back into the 8’x9’ Davis Brook box culvert. DWC #2 will provide access for the dewatering piping for Tank Cells #2 and #3.

Also on Monday, S.E. MacMillan began setting into place the precast sections of the three water supply chambers. The water supply chambers will hold valves and piping for supply to each of the nine tipping buckets.

VR placed 30 cubic yards of Hughes Brothers concrete on Tuesday for the DWC #2 foundation slab. This slab sits on top of the pile cap SEM built last week. VR also began tying steel and standing panels on the Tank top slab for the DWC #2 upper walls.

SEM began backfilling around the water supply chambers and damp proofing the Tank top.

By Wednesday the northern end of the Tank is backfilled to elevation 16.00 and has about half the top damp proofed.

VR continued to tie reinforcement steel and set forms for DWC #2 on Wednesday. SEM laid 4” underdrain along the north Tank foundation just below the upper slab elevation of 16.00. This underdrain will ultimately tie into the small soil-filter pond to be built on the south end of the Tank site.

DWC #2, in the photo, has the inside face of forms standing and VR is tying reinforcement steel.

Thursday MacMillan began backfilling on top of the Tank. They rolled out non-woven filter fabric over the damp proofing.

Friday morning VR had DWC #2 walls ready for concrete. Hughes Brothers delivered 50 cubic yards of concrete and Mainely Concrete Pumping pumped it into the forms.

Friday afternoon the first lift of gravel backfill covered the entire top of the Tank.

Work completed 9-27-21 to 10-01-21

On Monday S.E. MacMillan prepped form work and reinforcement steel for connecting the Tank to the Davis Brook CSO 8’x9’ box-culvert conduit. The connection required making two cuts into the concrete conduit, inserting two 48” ductile iron pipes from the conduit and into the tank and closing both penetrations with either non-shrink grout or concrete. They also continued with backfilling operations. S.W. Cole had a technician on site Monday. Subbase gravel compaction was verified beneath the concrete pile cap to be placed on top of the left-in-place soldier and sheet piles. The pile cap gives bedrock foundation support to the Dewatering Chamber #2. DWC #2 is the below grade concrete room where dewatering piping exits the Tank and is pumped to the Davis Brook CSO 8’x9’ box culvert conduit.

The southern end of the Tank is backfilled to the top of the roof slab at elevation 16.00. Finish grade will be at elevation 22.50.

This is looking south; all three Cell #3 tipping bucket bays are in view and SEM has a crew in the middle left of the photo prepping for the two 48” DIP connections from the existing Conduit to Tank.

Tuesday, SEM began cutting into the existing Conduit with plunge-cut concrete chain saws. They finished cutting one opening by mid-morning. Because of dry weather conditions the flow normally running in the conduit was re-routed to the still operational Penobscot Interceptor which runs parallel to the Conduit and was the original sewer main constructed in the early 1960’s.

The section of 48” DIP, approximately 26.00’ long is two pieces which they pre-belled before setting into place with the crane. They closed the form to the inlet connection to the Tank and filled the void with non-shrink grout. Hydrophilic water stop was placed around the concrete opening and around the pipe.

Wednesday, MacMillan cut the second opening into the Conduit. Installed the second section of 48” DIP, grouted the inlet to the tank and worked on the formwork necessary to close both 48” connections to the Conduit.

MacMillan finished both connections on Thursday, placing concrete for both Conduit closures and placing concrete to cradle both pipes securely onto the pile cap beneath them. They began tying steel for the concrete support cap reinforcing the Conduit vertically and horizontally where the penetrations were made.

On Friday MacMillan placed 30 cubic yards of Hughes Brother’s concrete over the reinforcement steel for the support cap of the Conduit.

Connecting the Tank to the Conduit was a significant milestone. MacMillan is expecting VR Concrete to return to the site next week to begin the final concrete work on site. Macmillan will now focus on backfill and installing the tipping bucket water supply chambers and the water supply piping for the tipping buckets.

Work completed 9-20-21 to 9-24-21

Rick Merrithew used a hydraulic plunge-cut concrete saw to cut concrete fill away from the Davis Brook conduit.

S.E. MacMillan began preparation for connecting the Tank to the Davis Brook 8’x9’ conduit which runs parallel to the tank on the Penobscot River side of the Tank. On Monday they began removing a two-layer protective wall which they put in place in the spring of 2020 as a shield against the 8’x9’ box culvert conduit.

Here against the southwest corner, SEM has screened Tank

excavation graded and compacted to about elevation 0.00 along the entire south

end and north to just beyond dewatering chamber #2.

On the west side screened fill has been graded into layers and compacted from the northwest corner south to near the dewatering chamber #2. MacMillan cut the shoring to about elevation 5.00 and removed the sheet pile tops.

Wednesday, Zach Fitzpatrick, from S.W. Cole, was on site and took density measurements to verify compaction.

SEM completed removing the concrete and block from the conduit face where the 48” Tank inlets will be connected to both the conduit and the Tank. They placed a one-inch thick steel plate over the sheet and soldier piles where the 48” inlet pipes will rest and a foot of concrete over it to make a pile cap which will support the inlet pipes. In the top concrete layer, they set two one-inch plates to grade. These surface plates will allow the ductile iron pipe to be shimmed to permanent finish grade with steel shims.

SEM has been dewatering all three Tank cells this week, pumping each cell into an individual silt sack placed inside an erosion control barrier. All three Tank cells are near empty of leak test water.

Brandi Piers, from the Maine Department of Environmental Protection was on site Thursday to view MacMillan’s progress.

Work completed 9-13-21 to 9-17-21

Work completed 9-7-21 to 9-11-21

On Tuesday, H.B. Fleming finished pulling the north ramp sheets and all north Tank sheets. From Tuesday through Thursday Fleming cut the east shoring wall sheets to about elevation 6.50 and pulled the sheet tops.

After Cell #3 sat all weekend full with water to elevation 11.65, a leak test was started on Cell #3 Tuesday morning. Several locations had water lightly weeping through the three-foot thick Tank walls. S.E. MacMillan injected an epoxy solution into those locations. On Friday the final measurement was taken on the water surface elevation in Cell #3, less than 0.01’ had been lost so the leak test was successful. MacMillan began damp proofing Cell #3’s exterior walls and grading two-feet of stone over the footing and against the south Cell #3 Tank wall. The entire Tank can now be backfilled to elevation 7.00. MacMillan has already backfilled Cell #1 to elevation 7.00 and will continue to grade and compact backfill layers from the northerly end of the east side of Cell #1 toward the south easterly Cell #3 Tank corner. S.W. Cole was on site Tuesday and Wednesday to take density tests for monitoring compaction.

MacMillan is using a sixty-foot H-pile to carry groundwater discharge hoses across the northeast Tank corner from a deep sump on the north west side of the excavation.

On Saturday MacMillan cut the last of the east-wall sheets and cut sheets from the south ramp east corner to the southeast Tank corner.

Work completed

8-23-21 to 8-27-21

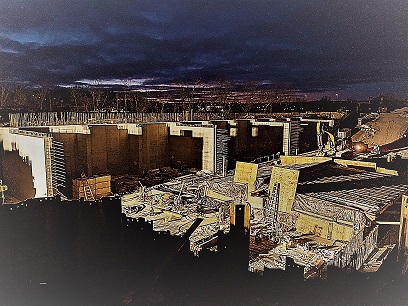

These five-foot high walls above the Tank will hold the flushing mechanisms for all nine Tank bays. Each of the three Cells has three bays. These concrete boxes will have precast covers fitting into a bonded-out shelf on their inside wall faces. Installation of the tipping bucket flushing mechanisms will begin this Fall.

On Monday, VR Concrete finished stripping the forms from the final tipping bucket wall placement. They began forming and tying reinforcement steel for the Tank vent chimney which passes through the top slab in the south west Tank corner. VR began breaking down and bundling shoring and decking from inside Cell 3 and stacking it onto of the tank for banding and return to the supplier.

The 54” diameter bond-out for the 48” Tank vent can be seen here. VR Concrete formed the chimney walls around it and tied the reinforcement steel before closing the outside face of the forms. VR placed the chimney walls on Tuesday.

On Wednesday a concrete hopper/bucket is lowered into Cell 3’s tipping bucket bay #2. Together SEM and VR used concrete buggies to place 10 cubic yards for the first section of partition walls in Cell 3. The partition walls separate bay 2 from bays 1 and 3.

SEM and VR formed the first partition wall section in Cell 3 on Monday and Tuesday and then placed concrete on Wednesday.

Also on Wednesday, VR placed the vent chimney slab.

The man in the shadow above is perched on top of a section of Cell 3 tipping bucket wall using a radio to guide the crane operator in putting the hopper/bucket where it’s needed. SEM and VR placed the second section of partition wall in Cell 3 on Thursday. They placed twenty yards with this 2 cubic yard hopper/bucket.

These partition walls are the final pieces of concrete inside Cell 3, completing concrete work inside the Tank.

Friday afternoon the partition wall forms had been stripped and craned out of Cell 3. The men in the lift on the left are caulking a wood barrier against the Cell 2 rising water leak test.

These photos were taken from the eastern weir shelf between Cell 3 and Cell 2. In the distance, through the weir between Cell 2 and Cell 1, the water elevation can be seen as full in both Tank Cells 1 and 2.

The leak test for Cell 2 began on Friday at 1:20 pm with the water elevation at 11.65. It is a three-day test. The water height will be measured again on Monday, August 30th at 1:20 pm. If the water level has not lowered by more that 3/8 of an inch, the leak test will be successful.

Work completed 8-9-21 to 8-13-21

Cell 1 was completely ready for leak testing on Monday.

On Monday S.E. MacMillan started setting up pumps and hoses to begin filling Tank Cell 1 with ground water. They estimated, based on an onsite flow test of existing ground water pumping that they could pump three to four feet of water into the tank in a twenty-four-hour period and reach the design water surface elevation in three days. Also on Monday, MacMillan prepped Cell 2 for tipping bucket radius fill concrete for all three bays and they plugged the three weir’s between Cell 1 and Cell 2 for the leak test.

VR Concrete finished cleaning Cell 2 and began tying reinforcement steel and forming partition walls.

On Tuesday VR finished forming and tying half of the partition walls in Cell 2 and placed concrete with the crane/hopper-bucket and concrete buggy.

Odin Steel finished tying reinforcement steel for elevated slabs 5 and 6. On Tuesday VR placed 70 cubic yards with the crane/hopper-bucket for ES 5.

Mainely Concrete Pumping was on site for ES 6 on Wednesday. Placing ES 6 completed the Tanks’ elevated slab roof. Hughes Brothers delivered 80 cubic yards for ES 6, Cell 2 tipping bucket radiuses and Cell 2 partition walls.

MacMillan placed tipping bucket radius fill with the crane/hopper-bucket on Wednesday.

Cell 1 leak test water was at elevation 7.00 Thursday morning at 6:30.

SEM and VR placed the remainder of the partition walls in Cell 2 on Thursday.

The concrete buggies are converted to be powered with propane inside the Tank to maintain air quality.

Cell 1 leak test water level was at elevation 10.00 on Friday morning, nearing the Tank design water surface elevation of 11.65.

Work completed 8-2-21

to 8-6-21

S.E. MacMillan worked the first three days of the week completing the finishing touches necessary prior to the start of leak testing Cell 1. The above photo shows Cell one’s northeastern Riverside corner with tipping bucket radius concrete in place, and minor patching and grinding complete. The entire floor of the foundation slab was touched up with a concrete “plainer” - which looks like a floor sander. All tie holes are plugged and other imperfections have been filled with grout or ground down. MacMillan plans on starting the Tank leak testing in Cell 1 next week.

VR Concrete Placed tipping bucket wall section 4 on Tuesday. They moved shoring and decking from out of Cell 3 up top and are breaking most of it down for organizing, banding and return. Weds. and Thurs. they moved shoring and decking into Cell 3 for the final elevated slab sections, 5 and 6.

Thursday, in the off and on rain, VR finished shoring and decking ES 5 and 6 ahead of Odin Steel starting to tie reinforcement steel for ES 5. The above photo shows the southeast Riverside sections of the Tank where VR was putting down the last pieces of plywood for ES 6.

Thursday and Friday MacMillan and VR worked together lowering shoring towers, getting them onto rollers and rolling them to the tipping bucket openings in Cell 2 for rigging and removal from the tank with a crane.

Odin finished reinforcement steel for both ES 5 and 6 on Friday.

Work completed 7-26-21 to 7-30-21

S.E. MacMillan finished placing fill concrete in Cell 1 this week. They plugged form-tie holes with mechanical plugs and non-shrink grout. They stripped the formwork for the partition walls in Cell 1 which were placed last Friday.

On Tuesday SEM placed the second lift of fill concrete in the Cell 1 sump channel.

V.R. Concrete finished forming tipping bucket wall section 3 and placed 90 cubic yards of Hughes Brothers concrete with the crane and a hopper-bucket on Tuesday for elevated slab section 4. There are four more tipping bucket wall sections to place and two more elevated slab sections.

Finish grade will be approximately 18” above the formwork in this photo – 34 feet above the Tank foundation bottom. None of the structural concrete work will be visible when the Tank is finished.

SEM spent the entire week prepping Cell 1 for leak testing. They plugged form-tie holes, drilled/cored wedge anchors out of the slab, coated shrinkage cracks with an epoxy coating and began plaining/grinding the rough surface areas on the tank slab.

VR received concrete compressive strength break results for ES sections 11 and 18 which indicated they could begin removing shoring and decking from beneath both sections. The photo above shows Cell 3 with shoring under ES sections 17,18,11 and 12. The open are will be shored and decked for ES sections 5 and 6.

SEM had a crew all week screening excavation in the Roundhouse fill site to be used as backfill for the Tank. Leak testing will start in August and Tank backfill will start in the end of September.

Work completed 7-19-21 to 7-23-21

On Monday, S.E. MacMillan placed 2 cubic yards of Hughes Brothers concrete with the crane and bucket for the second lift of the Cell 3, bay 2 tipping bucket radius.

VR Concrete built the tops of the construction joint bulkheads for elevated slab sections 11 and 18. They continued moving shoring and decking support into Cell 2 for elevated slab sections 3 and 4, and they began putting down decking plywood. Odin Steel tied reinforcement steel for the vent stack chimney walls in Cell 1. They finished the top mat reinforcement for elevated slab section 12.

VR finished shoring and decking ES sections 3 and 4 in Tank Cell 2 on Monday.

On Tuesday Odin tied the bottom reinforcement mat for ES sections 3 and 4 and started tying the top mat. VR built the middle third of the construction joint bulkhead between ES 3 and 4.

On Tuesday morning MacMillan placed another two cubic yards for the second lift of the Cell 3, bay 3 tipping bucket radius. In the afternoon they placed 10 more cubic yards for the first lift of tipping bucket radius fill in Cell 1, bays 1, 2 and 3.

VR, with Mainely Concrete Pumping, placed 210 cy of Hughes Brothers concrete for ES sections 11 and 18. Wednesday, Odin took delivery of the last of 1,680,000 lbs. of Tank reinforcement steel. They also completed tying the top mats for ES sections 3 and 4.

Thursday morning VR used the crane to bucket concrete into Cell 1 for the first section of partition wall. Mainely Concrete Pumping was also on site to pump 290 cy for elevated slab sections 3, 12 and 17.

With the placing of ES sections 3, 12 and 17 on Thursday

only three sections remain; ES sections 4, 5 and 6. MacMillan placed concrete

on Friday with the crane and bucket inside Cell 1. They put down the first lift

of the sump channel and the second lift for Cell 1, bay 2 tipping bucket

radius.

Work completed 7-12-21 to 7-16-21

Stanley MacMillan discusses strategy with Jerimiah Kennett and Bob McKinnon from VR Concrete.

On Monday, S.E. MacMillan built an access ramp to reach from finish grade on the southwest Tank corner to top of concrete on the southwest corner elevated slab. MacMillan also worked on preparing for leak testing the tank by plugging tie holes in Cells 2 and 1.

VR Concrete moved shoring/decking from Cell 2 to cell 3, took down edge forms and scaffold railing on the column line G wall, stripped formwork on the first Cell 1 tipping bucket wall placement and began setting edge forms for the elevated slab sections 17 and 18 on column line 7.

On Tuesday Macmillan continued plugging form tie holes and organized form panels for return to the supplier.

Inside of Cell 1 Macmillan is plugging approximately 800 form tie holes with mechanical plugs capped with non-shrink grout.

VR moved the remaining formwork from cell 2 and set shoring and decking into Cell 3 on Tuesday, they continued building edge forms against the southern Tank wall on column line J and began to put plywood down on the decking support for the elevated slab sections in Cell 3.

SEM began screening backfill material at the Roundhouse excavation stockpile on Wednesday. They set the southwest corner Tank access ramp into place and prepped Cell 3 tipping bucket radiuses for the first lift on concrete fill. VR continued putting plywood onto shoring/decking support in Cell 3 for elevated slab sections 11,12,17 and 18. They finished the edge forms for elevated slab sections 18 and 12 and built scaffold for work on tipping bucket wall sections in cell 2.

Odin Steel tied reinforcement steel for the column caps in elevated slab sections 17 and 18, and they tied the bottom mats for elevated slab sections 18 and 11.

On Thursday SEM placed the first lift of fill concrete in Cell 3, bays 1,2 and 3 for tipping bucket radiuses.

VR built the construction joint bulkheads separating elevated slab sections 11,12,17 and 18. They began to erect and move shoring/decking into Cell 2 for elevated slab sections 3 and 4, and they began to put plywood down for section 4.

Odin tied reinforcement steel for the top mats of elevated slab sections 11 and 18 on Thursday and finished the top mat for section 11 on Friday.

This is the Cell 3 in the southeast corner of the Tank. These last two elevated slab sections will be shored, formed and placed in the 1st or 2nd week of August.

This is Tank Cell 2 on Thursday, July 15th. In the upper left photo corner elevated slab section 4 is shored, partially supported and decked. Mid and lower right in the photo shows elevated slab section 3 still needing a few shoring towers, beam supports and plywood decking. VR Concrete was off on Friday.

Friday, Macmillan put their job-built swing-screed into place to rough finish the 48” radius placed on the Tank slab beneath the tipping buckets. They placed 2 cubic yards of Hughes Brothers concrete with the crane and hopper-bucket for the Cell 1, bay 1 radius. This radius will redirect the flushing water, or channel the force of the flushing water around a 90 degree, vertical to horizontal bend from the tipping buckets into each bay of each Tank cell. Each tipping bucket holds 1,137 gallons of flushing water and this water will fall approximately 25 feet from the bucket to the radius/bend in the concrete Tank floor. This flushing water and its velocity will clean each Tank bay of solids and residue left on the tank floor after the tank has been pumped out from a CSO event.

Work progress 7-5-21 to 7-9-21

On Tuesday, after the Monday holiday, S.E. MacMillan worked on the retaining wall in the south shoring ramp. This retaining wall will hold a crane pad similar to the one they built in the north shoring ramp. SEM also stripped the scaffold, form ties and hardware from wall section 10. VR Concrete placed 33 cubic yards of concrete delivered by Hughes Brothers for the first section of tipping bucket walls (TB1) in Cell 1, bays 1 and 2. They also continued moving shoring/decking from Cell 2 into Cell 3.

MacMillan finished the retaining wall and crane pad on Wednesday, plugged tie holes in Cell 1 and began stripping forms from Cell 3 columns. VR moved their 250-ton crane from the north ramp to the south ramp. They stripped form work from the first tipping bucket wall placement and began forming TB wall placement #2.

On Thursday SEM built stairs for access from the south ramp crane pad to the Tank Cell 3 footing and began building a ramp which will make access from existing grade to the southwest corner elevated Tank slab.

VR stripped TB 1 form work, finished forming TB 2 and on

Thursday placed 20 cubic yards delivered by Hughes Brothers for wall section

TB2. Walls over the tipping buckets are now complete in Cell 1 for bays 1 and

2. Both tipping bucket wall sections were placed with the crane and a

hopper-bucket. Friday’s work was shortened by rain. MacMillan did not work. VR

moved shoring/decking from Cell 2 to Cell 3 and left at 10:00 am on Friday when

the rain began to settle in.

Work completed 6-28-21 to 7-2-21

Devin Haight cleaned the water stop and construction joint for wall section 10. The wall dowels in this section were cut and had mechanical couplers attached for reinforcement continuation. The dowels were cut and a ramp was built over this Cell 1 wall section for crane and concrete pump truck access which would enable boom reach for Cell 2 concrete and material placement.

On Monday Odin Steel tied reinforcement steel for wall section 10. S.E. MacMillan drilled and doweled reinforcement steel for tipping bucket walls in Cell 1, pulled half column forms from Cell 3 columns and SEM trucks hauled fill for Thornton Construction to the Concert Venue on Railroad Street.

VR Concrete received results from S.W. Cole showing seven-day concrete compressive strength testing results for elevated slab sections 9 and 16. The breaks indicated a 7-day strength greater than 70% of ultimate design strength. With this favorable information they began lowering the shoring and decking in Cell 2 beneath elevated slab sections 9 and 16. All the shoring and decking will need to be removed from elevated slab sections 9,10,15 and 16 before another elevated slab section can be shored, decked and placed. VR worked all week on lowering and stripping the shoring and decking for elevated slab sections 9 and 16.

Odin finished tying steel for wall section 10 and MacMillan completed and closed the formwork on Wednesday.

These two photos, taken 364 days apart, (above) show the final full height wall section and columns being placed this week on Tuesday, and (below) one year ago, the first concrete placement in the northeast Tank corner of Tank slab section 1. MacMillan has placed just over 7,000 cubic yards of concrete during the past 12 months.

One year ago, H.B. Fleming had completed half of the Tank shoring as S.E. MacMillan was beginning to place concrete.

On Thursday Hughes Brothers delivered 123 cubic yards of concrete and an N.S. Giles’ pump truck pumped it into the forms for wall section 10 and the final five columns.

VR worked on tying reinforcement steel and erecting form work for the first section of tipping bucket walls in Cell 1. Odin set into place and tied reinforcement steel for the final five Tank columns in Cell 3. SEM began building a retaining wall and filling behind it in the south ramp to accommodate VR’s 250-ton Grove crane which will be moved to the south ramp next week.

Work completed 6-21-21 to 6-25-21

On Monday Odin Steel tied bottom mat reinforcement steel for elevated slab section 15.

This week S.E. MacMillan hauled approximately 4,000 yards of fill from the Roundhouse fill site to the Darling’s Waterfront Pavilion. Thornton Construction is having SEM haul 14,000 yards to the concert venue as part of site modifications in anticipation of coming music events. SEM also stripped off the temporary walkway decking over the Cell 3 sump channel. All three sump channels will get concrete fill to create a 1% slope across the Tank’s west side. The channels will then be pitching toward a sump. Each Cell has a five-foot deep sump channel running along the west side of the Tank, along with a five-foot deep sump on one end below the channel and a chopper pump mounted in the sump. Once on-line, after a CSO event, the three Tank chopper pumps will pump the captured CSO water out of each cell and back into the Davis Brook box-culvert conduit for subsequent treatment further downstream at the Bangor Waste Water Treatment Plant.

Monday and Tuesday VR Concrete built construction joint bulkheads and edge forms for elevated slab sections 1, 2, 10 and 15. SEM continued to plug form tie holes.

Odin tied top mat reinforcing for elevated slab section 15 and bottom mat reinforcing for elevated slab section 10. VR and SEM worked together, along with an N.S. Giles pump truck and S.W. Cole Engineering on Wednesday to place 120 cubic yards for elevated slab sections 2 and 15.

VR and SEM used one of the site cranes and a two-yard hopper bucket on Thursday to place 65 cubic yards provided by Hughes Brothers for elevated slab section 1.

Hughes Brothers delivered a total of 190 cubic yards between 9:00 and 3:00 on Thursday for elevated slab sections 10, 1 and the Cell 3 sump channel. N.S. Giles pumped the concrete, VR and SEM placed and finished it.

Work completed 6-14-21 to 6-18-21

On Monday VR Concrete built shoring and decking supports for elevated slab section 1. Odin Steel tied reinforcement steel for elevated slab section 16. S.E MacMillan started plugging form tie holes in Cell 3.

This photo shows elevated slab sections 1 and 2 on Wednesday with completed shoring and decking. Once these two sections are placed the elevated slab will be complete on Tank Cell 1. Odin worked on tying steel Tuesday and Wednesday for elevated slab section 16. VR built construction joint bulkheads and edge forms for elevated slab sections 15, 16, 1 and 2. SEM continued to plug tie holes in Cell 3 and bolted together column forms for Cell 3 columns I-2, I-6, H-2, H-3 and H-6.

On Thursday Odin began tying steel for elevated slab sections 1 and 2, they completed the bottom mat and on Friday finished the top mat. Elevated slab sections 1 and 2 were shored, decked and had 35,000 pounds of reinforcement steel tied into place this week.

MacMillan prepped Cell 3 all week for leak testing to be done later this summer. They are plugging form tie holes with mechanical plugs and non-shrink grout.

On Thursday, SEM and VR placed concrete for Cell 2 elevated slab sections 9 and 16 along with Cell 3 columns I-2, I-6, H-2, H-3 and H-6. Mainely Concrete Pumping pumped 218 cubic yards of concrete delivered by Hughes Brothers.

Each column is filled to half full, vibrated and them filled to finish grade and vibrated again. Each two-foot diameter column takes 3 cubic yards of concrete.

Work completed 6-7-21 to 6-11-21

VR Concrete removed shoring and decking from Tank Cell 1.

On Monday, Odin steel tied wall-to-slab dowels for wall section 15 and column-to-elevated slab reinforcement for columns H-2, H-3, H-6, I-2 and I-6. VR Concrete built edge forms and scaffold railing along the west Tank wall for elevated slab sections 15 and 16. They set shoring tops to grade and began decking Cell 2 for elevated slab sections 9,10,15 and 16. They moved the final seven shoring towers from Cell 1 into place in Cell 2. S.E. MacMillan worked on installing wall form ties for wall section 15 along with building scaffolding and the construction joint bulkhead at the joint for sections 10 and 15. Wall section 10 is the last remaining full height wall section. This wall section is being left out for now so the concrete pump can set-up on the Cell 3 foundation slab and have the reach to pump elevated slab sections 9,10, 15 and 16.

Tuesday, Hughes Brothers delivered 190 cubic yards of concrete. The placement for wall section 15 was pumped by N.S. Giles, tested by S.W. Cole and placed by S.E. MacMillan. VR decked Cell 2 elevated slab sections 9,10, 15 and 16.

On Wednesday Odin tied reinforcement steel for elevated slab sections 9 and 16. SEM stripped ties, Hardware and scaffolding from wall section 14. VR build edge forms and bulkheads for elevated slab sections 9,10, 15 and 16.

SEM stripped gang forms from wall section 15 on Thursday. VR started building and setting shoring into Cell 1 for elevated slab sections 1 and 2. Odin tied steel for elevated slab sections 9 and 16.

On Friday VR built and stood shoring and decking support in Cell 1 for elevated slab sections 1 and 2. SEM set crane mats onto the foundation slab in Cell 3 as a landing spot for the concrete pump truck to pump two elevated slab sections scheduled to be placed next week.

Retired City Engineer John Frawley and retired Waste Water Treatment Plant Superintendent Ralph Mishou visited and took a tour of the site this week. Between the 1960’s and the 1990’s these two guided Bangor through the design and construction of Bangor’s Primary and Secondary Sewer Treatment facilities. Together they represent over 60 years of engineering and water quality service to the City of Bangor.

Work completed 6-1-21 to 6-4-21

VR Concrete began moving shoring and decking from Tank Cell 1 into Cell 2.

On Tuesday, the day after the Memorial Day Holiday, there were twenty-five men on site. VR Concrete and S.E. MacMillan worked together on wall section 14. They stripped the column forms for E-3, E-4, F-3, F-4 and F-5 and stood half forms for Cell 3 columns H-2, H-3, H-6, I-6 and I-2. The weir bond-out for wall section 14 was installed into the form, scaffold and railing was built, turnbuckle braces were erected and the construction joint bulkhead between wall sections 14 and 15 was constructed. Odin Steel started ground tying reinforcement steel for wall section 15. They completed 2 mat sections of the 6 total and rigged them for the crane to set into place for the wall section 15. They also started tying wall-to-elevated slab dowels for wall section 14 and the extra diagonal reinforcement steel framing the wall 14 weir bond-out.

Wednesday morning Odin finished tying wall 14 wall-to-elevated slab dowels along with the extra reinforcement around the weir bond-out. Late morning, Hughes Brothers arrived with concrete for wall section 14. N.S. Giles pumped, S.W. Cole tested and MacMillan placed the 240 cubic yards delivered by Hughes Brothers between 10:35 am and 3:45 pm.

MacMillan is a week or two away from completing the full-height wall sections for Tank Cell 3.

This week VR concentrated on elevated slab shoring and decking. They moved whole sections of shoring and decking from Tank Cell 1 to Cell 2. In a holiday shortened work week they moved 26 sections.

Thursday Odin tied column reinforcement steel into place for columns I-2, I-6, H-2, H-3 and H-6. They ground tied the four remaining reinforcement steel sections for wall 15 and then had them rigged and lifted into place with the crane. MacMillan stripped the construction joint bulkhead, hardware and scaffold for wall section 14. They began setting gang forms in place for wall section 15.

On Friday Tank Cell 1 had seven shoring/decking sections left below the elevated slab.

Also on Friday, MacMillan stripped gang forms from wall section 14. They cleaned and oiled them, stood them into place for wall section 15 and installed form ties and turnbuckle bracing.

Work completed 5-24-21 to 5-28-21

Monday, Odin Steel set ground-tied reinforcement mats for wall section 9 into place with S.E. MacMillan’s crane. VR Concrete and SEM worked together on removing form ties, hardware and scaffold ahead of moving gang forms from wall section 13 to wall sections 9 and 14.

Tuesday, VR took delivery of another load of elevated slab shoring and form decking. Odin ground-tied reinforcement steel for wall section 14 and set into place one wall section 14 reinforcement mat and the remaining five column reinforcement cages for Cell 2. SEM stripped wall 13 formwork and stacked gang forms on the foundation slab for cleaning. VR and SEM set both faces of wall section 9 formwork and closed the formwork for the five Cell 2 columns.

Wednesday morning Odin tied the wall-to-slab reinforcement dowels for wall section 9. VR and SEM built the construction joint bulkhead at the intersection of 9 and 14.

Wednesday afternoon Hughes Brothers delivered 104 cubic yards which was pumped by N.S. Giles and placed by VR and SEM. Wall section 9 was completed as well as columns E-3, E-4, F-3, F-4 and F-5. This placement brought the total concrete quantity to 1476 cubic yards for the month of May.

VR worked all week on stripping the formwork and plywood in Cell 1 from around the column capitals. They are lowering all the shoring/decking in order to put rollers under each shoring tower. The shoring towers will be rolled toward the eastside of Cell 1 where elevated slab sections 1 and 2 still need to be placed. Through these openings VR is rigging the shoring/decking towers and lifting them in one piece from Cell 1 to cell 2. Elevated slab sections 1 and 2 will be placed after all the shoring/decking for sections 7, 8, 13 and 14 have been moved from Cell 1 to Cell 2.

SEM has completed side slopes, gravel and loam for the new access road and parking lot to the Essex Woods Trail system. Hydroseeding will take place June 1st.

Work completed 5-17-21 to 5-21-21

VR Concrete and Odion Steel were not on site this week.

S.E. MacMillan graded subbase stone, tied the top and bottom mat of reinforcement steel, installed forms and form ties, column dowels for columns I-3 and I-4, starter wall forms for the J-line starter wall and water stop for slab section 10.

Slab section 10 is the last of fifteen foundation slab sections. MacMillan placed the first slab section on July 2nd of last year.

Tank Cell 2 is on the right, Cell 3 on the left. In the center is the full height G-line wall separating the two. The reinforcement bars sticking out of the top will tie the wall into the 20” elevated top/roof slab. When VR Concrete returns next week, together with S.E. MacMillan they will complete the G-line wall with two wall placements, wall sections 9 and 14. They also will begin removing shoring from Cell 1 with the crane for re-setting into Cell 2.

MacMillan placed slab section 10 on May 19th. Hughes Brothers delivered 190 cubic yards of concrete, Aaron McGinnis, their quality control specialist managed the control of air entrainment and slump. Brendan Auth, a concrete testing technician for S.W. Cole verified the air and slump for the City of Bangor. Ben Cookson pumped the concrete with an N.S. Giles pump truck.

MacMillan has a crew working on finishing the access road, parking lot and trails for the new Essex Street entrance to the Essex Woods Trail system. Side slopes are being loamed, final gravel grade is being established and hydroseeding is scheduled for next week.

Work completed 5-10-21 to 5-14-21

On Monday Stanley MacMillan and N.S. Giles pump truck operator Ben Cookson, watched the placement of slab section 9. O.J. Folsom delivered 216 cubic yards, pumped by Giles and placed and finished by S.E. MacMillan.

Odion Steel tied bottom mat reinforcement steel for elevated slab sections 8 and 13. VR Concrete built construction joint bulkheads for 8 and 13.

MacMillan placed slab section 9 on Monday leaving only two more foundation slabs to place.

Devin Haight, Cody Hotham, James McClure, James King, Ian

Hotham, Richard Grumbach and Earl Grover placed and finished slab section 9.

On Tuesday, VR continued building bulkhead formwork for

elevated slabs 8 and 13 and Odion tied reinforcement steel for 8 and 13.

MacMillan graded subbase stone for slab section 15.3b and tied reinforcement

steel for 15.3b top and bottom mats.

Wednesday Folsom delivered 220 cubic yards, pumped by N.S. Giles, which VR placed as elevated slab sections 8 and 13.

MacMillan tied column line J full height wall reinforcement steel for slab section 15.3b and stood form panels and installed form ties.

This is the inside of Tank Cell 1 looking toward the northwest corner. Four of six Cell 1 elevated slab sections have been placed. More shoring will be erected in order to support placement of the final two Cell 1 elevated slab sections.

The right side of the photo shows a bit of shoring, elevated slab sections 8 and 14 and full height Tank wall for Cell 1. The column forms center and left are all in Tank Cell 2. Tank Cell 2 needs two more wall placements (#14 and #9) and it will be ready for elevated slab shoring, formwork and reinforcement steel. The elevated slabs for Cell 2 will be placed in June.

Thursday, Folsom delivered 210 cubic yards pumped by Giles

and placed by MacMillan for slab section 15.3b. One more slab section, #10, is

needed to complete the Tank Cell 3 foundation slab.

Work completed 5-3-21

to 5-7-21

On Monday, VR Concrete placed 143 cubic yards of O.J. Folsom concrete; 128 cubic yards for wall section 13, and 15 cubic yards for columns E-2, E-5, E-6, F-2 and F-6. N.S. Giles provided the concrete pump. VR also built construction joint bulkheads for elevated slab sections 7 and 14. Odion Steel tied reinforcement steel for elevated slab sections 7 and 14.

S.E. MacMillan started the week forming and tying reinforcement steel for slab section 15.3a.